When starting a business no one thinks about the packaging of their products, but the packing of your products can be very important. Firstly it makes your business stand out if you package your products with branded packaging but secondly and most importantly the packaging you use can protect your products.

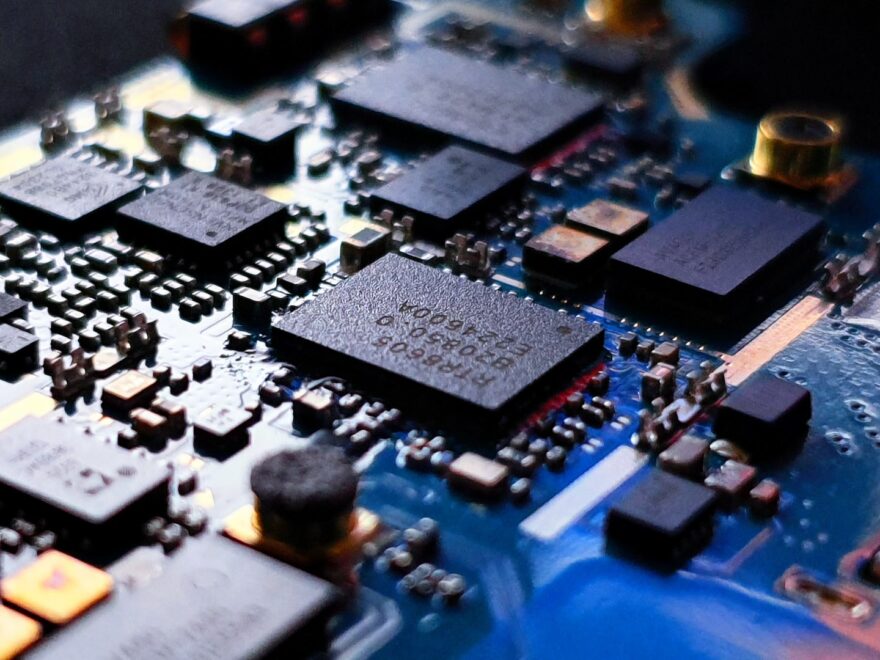

Today we will be talking about anti-static packaging. Anti static packaging or ASP as it is known in the industry can really benefit your business and can even be beneficial to non-electronic consumer products too.

But why even go through all of this bother? Simply because electronics can be damaged by electricity. Electrostatic discharge is well known in the manufacturing industry and it can cause serious damage to both people and items.

What is ESD?

ESD is Electrostatic Discharge and if you have ever had a little shock when you have touched a person or an object you will have experienced it. ESD in most cases will cause little to no damage to our bodies but to electronic goods, it can cause serious damage.

ESD occurs when friction, heat, pressure and induction cause electrons to move freely from one surface to another, when this happens it will cause a shock of discharge to the other surface that is being touched.

In the workplace, some companies install something known as ESD flooring which stops friction from occurring when high volume footfall is present.

Why does electrostatic discharge damage electrics?

Most electronic components because of their size can only work with a small change in temperature, this is known as its thermal mass. When this thermal mass is increased rapidly beyond its capabilities it causes the electronic component to fail.

How can you reduce anti-static within the manufacturing process?

You can reduce anti-static damage in the workplace by having a clear policy on the best practices. You can also purchase additional equipment such as ESD flooring, wristbands, static-resistant uniforms and even ESD mats. Using all of the above will cut down on ESD damage within the workplace.

Even with all of the above in place you will never be able to eliminate ESD especially if you post items to clients or customers. ESD can be caused by friction which can happen during the delivery process. To minimise the chance of ESD damage during delivery you can use anti static packaging.

What is anti-static packaging?

Anti-static packaging or ASP can come in different forms but they work by preventing static electricity from building up and discharging during the packaging and processing of your goods.

When your electronic components are placed in anti-static packaging they are protected until they are taken out again by the other side. Anti-static additives can be added to many materials which then can be used in many different fields including medical, manufacturing and many more.

Anti-static additives can be used in tubes, film and bags to help prevent damage to your devices.

What are the benefits of using ASP in your business?

If you are a business that handles electronic items then ASP can be used to cut down on damage and make your business more profitable. Experts estimate that 33% of all electronic damage is caused by electrostatic discharge.

Using anti-static packaging in your business will reduce the number of damaged goods from ESD. This will then reduce your business costs and make your business more profitable. This also means that your business will have to spend less time dealing with returns.

Less damaged items also mean better customer satisfaction.

Different types of packaging.

Know you know the benefits of ASP and that it comes in many forms, lets take a look at those forms so you know what it means for your business.

Static-Dissipative packaging.

Static-dissipative bags are often pink in colour and are an economical option to provide protection against static dissipation. There are best used when shielding against static fields is not important.

Static Shielding

Static shielding can come in many forms including tubes and bags. These protect your products from electrostatic fields and consist of three layers. These layers are static dissipative, suppressive electrical and a thicker protective layer to protect against wear, tears and punctures. This outer layer is often made of polyester.

Black Conductive

Black conductive tubing is often used in packaging too. It consists of black conductive tubing also known as carbon-load polyethene and it is used by companies to protect against isolated static charges.

Summary

Packaging is often an afterthought but when you operate with electrical goods it should be a priority. Having ASP in place will allow you to run your business to a higher standard and increase customer satisfaction.